Introduction to Large Diameter Straight Seam Submerged Arc Welded Steel Pipe Production Line

Wang Huiling(23)

System Developing for Joint Test Machine

The system of joint test machine loading stand which introduced into from American is introduced, thesystem can detect many technique target such as the maximum tensile strengthen , the maximum compressivestrength. The article deseribes the system scheme, software design, benefit and effect, as well as theindustrialization foreground.

Subject terms: oil casing test machine system scheme software design benefit

Wang Wenbo,Zhang Heping(27)

Application on the Double- Wings Funlike- Pipe High Frequency Welded Forming in One - off Technology

A ceording to the domestie funlike pipe welded technology condition and market demand, based on theapplication of high frequency welded theory, relying on the equipment and production process , the articleanalyzes and deseribes the application of double- wings funlike- pipe high frequeney welded forming in one-off technology. At the meantime, the adjustment and procedure control of produetion are introduced too.

Subiect terms: market current situation high frequency welded funlike pipe funlike pipe welded equipment process application foreground

Xia Yueliang(29)

High Frequency Power Welded Aluminum- Pipe

Subiect terms: Welded power high frequency welder welded aluminum- pipe

He Shuiping(30)

The Complex Material Roller Casting by Electrical Slag

The complex material roll and corresponding heat- treatment process are introduced. The new kindprocess make roll possess pure chemical composition, uniform metallurgical structure, stable mechanicalproperties, as well as prolong the performance life.

Subiect terms: roll complex material heat-treatment properties

Zhao Dong, Zhao H ongsheng,Zhang Xiaow ei(32)

Steel Pipe Full- Auto Developing and Printing Sign Equipment

The seleetion of technical parameter of steel pipe full- auto developing and printing sign equipmentwhich meet suecession industrial manufacture are introduced. The article deseribes the structure andcharacteristic of MAGNEM AG sign equipment, which introduced into from DANMARK.

Subiect terms: steel pipe developing and printing sign equipment

Zhang Yuanshen.Li Yanfen(35)

Introduce on Production Line of Large Diameter Longitudinal Submerged Are Welded Pipe

The article introduces the longitudinal submerged are welded pipe which were applied on oil and gas ofthe long distance pipeline and introduced into firstly in our country, though the comparison between JCO andUO, the paper propose some suggestion on constructing production line of longitudinal submerged are welded pipe.

Subject terms: JCOE longitudinal submerged arc welded pipe process equipment

Zhang Junchai,Zhang Antai,Liu Yi( 38)

The Pass Design of Door- Frame Section

Through the analysis on production process of cold bend steel unit, the article give out reasonable strip steel deforming grape. The flexible design of universal level roller are adopted then, it can not only better effectively rolling defect but also meet the accuracy requirement of product.

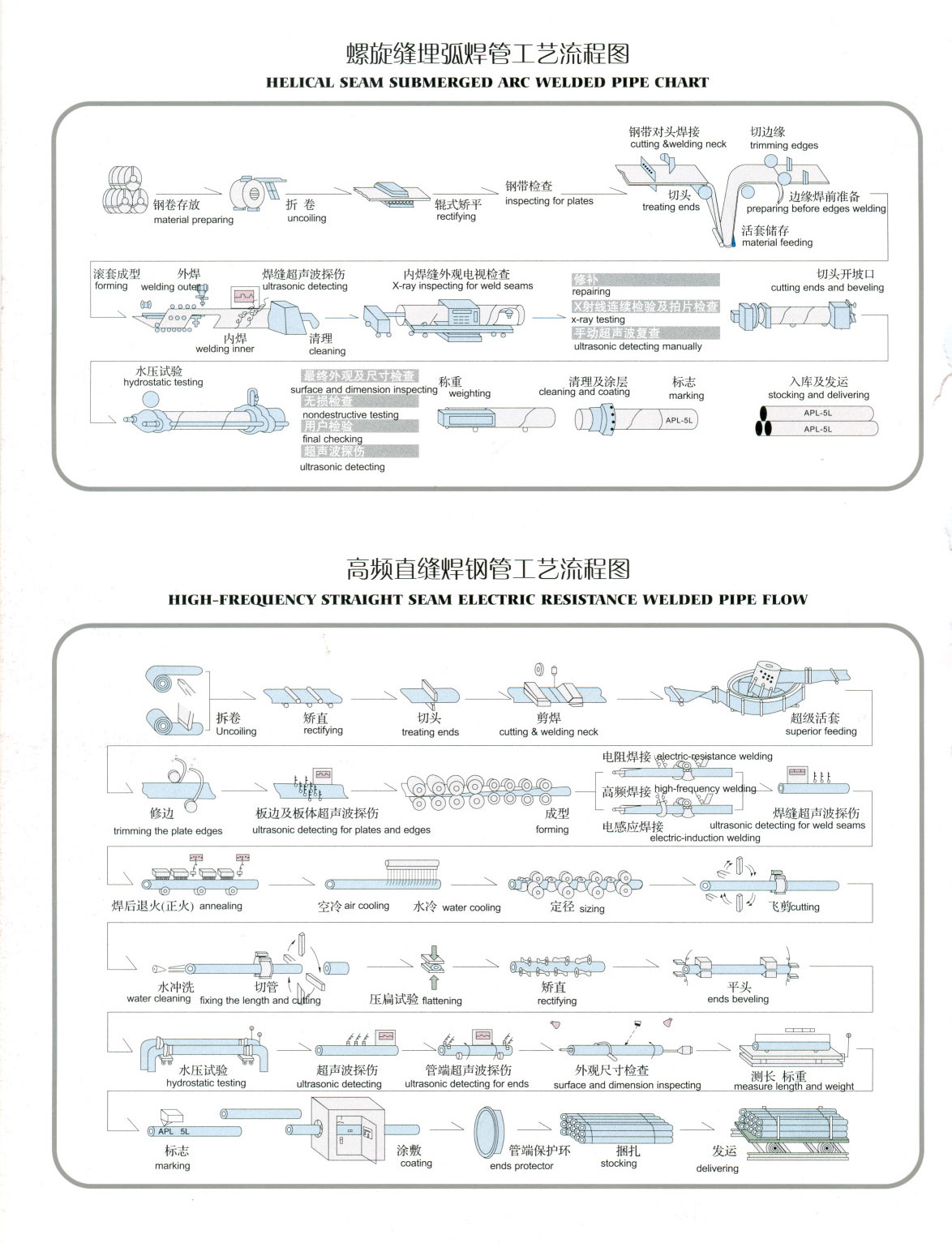

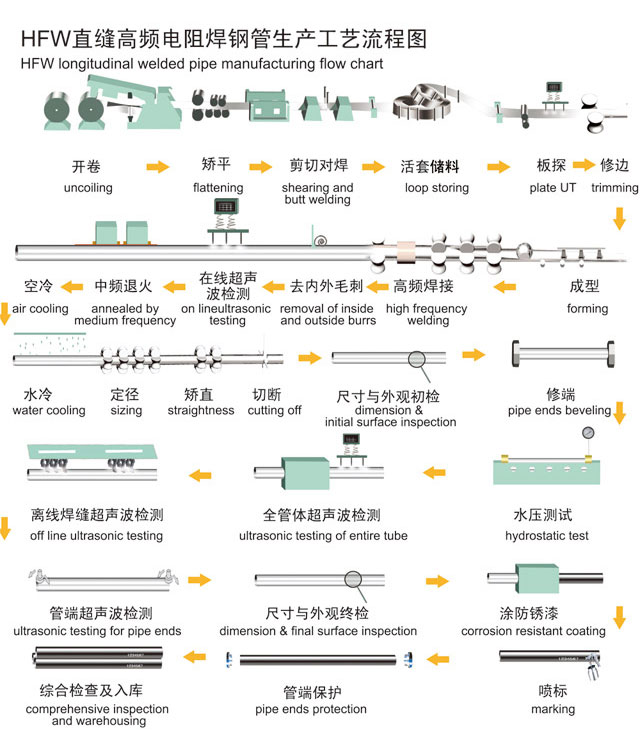

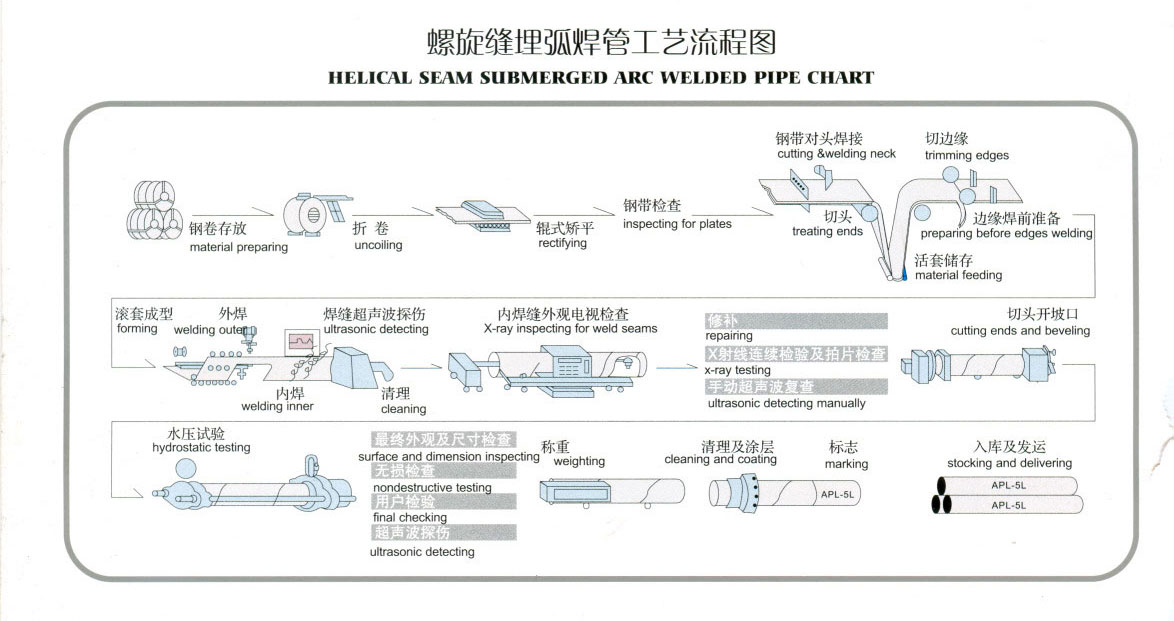

Spiral steel pipe production process

Spiral steel pipe production process: It is a spiral seam steel pipe made of strip steel coil as raw material, often formed by warm extrusion, and welded by automatic double wire double-sided submerged arc welding process

(1) The raw materials are strip steel coils, welding wire, and flux. Strict physical and chemical tests must be conducted before investment.

(2) The head and tail of the strip steel are connected by single or double wire submerged arc welding, and automatic submerged arc welding is used for repair welding after being rolled into a steel pipe.

(3) Before forming, the strip steel undergoes leveling, trimming, planing, surface cleaning, conveying, and pre bending treatment.

(4) The use of an electric contact pressure gauge to control the pressure of the oil cylinders on both sides of the conveyor ensures the smooth transportation of the strip steel.

(5) Adopting external or internal control roller molding.

(6) Adopting a weld seam gap control device to ensure that the weld seam gap meets the welding requirements, the pipe diameter, misalignment, and weld seam gap are strictly controlled.

(7) Both internal and external welding are carried out using American Lincoln welding machines for single or double wire submerged arc welding, in order to obtain stable welding specifications.

(8) The welded seams are all inspected by an online continuous ultrasonic automatic damage tester, ensuring 100% non-destructive testing coverage of spiral welds. If there is a defect, it will automatically sound an alarm and spray a mark, and production workers will adjust the process parameters accordingly to eliminate the defect in a timely manner.

(9) Use an air plasma cutting machine to cut steel pipes into individual pieces.

(10) After cutting into single steel pipes, each batch of three steel pipe heads must undergo a strict initial inspection system to check the mechanical properties, chemical composition, fusion status, surface quality of the welded joints, and undergo non-destructive testing to ensure that the pipe manufacturing process is qualified before it can be officially put into production.

(11) The parts with continuous ultrasonic testing marks on the weld seam shall be manually inspected by ultrasonic and X-ray. If there are indeed defects, they shall be repaired and undergo non-destructive testing again until it is confirmed that the defects have been eliminated.

(12) The pipes where the welded joints of the strip steel and the T-shaped joints intersecting with the spiral welds are located are all inspected by X-ray television or film.

(13) Each steel pipe undergoes a hydrostatic pressure test, and the pressure is sealed radially. The test pressure and time are strictly controlled by the steel pipe water pressure microcomputer detection device. Automatic printing and recording of experimental parameters.

(14) Mechanical processing of pipe ends to accurately control the perpendicularity, slope angle, and blunt edge of the end face.

The characteristics of spiral steel pipes include simple production process, high production efficiency, low cost, and rapid development of straight seam welded pipes. The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. It can produce welded pipes with larger diameters using narrower billets, and can also produce welded pipes with different diameters using billets of the same width. However, compared to straight seam pipes of the same length, the weld seam length increases by 30-100%, and the production speed is lower. Therefore, smaller diameter welded pipes mostly use straight seam welding, while large-diameter welded pipes mostly use spiral welding

Spiral tube and its standard classification: Spiral seam submerged arc welded steel pipe (SY5036-83) for pressurized fluid transportation is mainly used for pipelines transporting oil and natural gas; Spiral seam high-frequency welded steel pipe for pressurized fluid transportation (SY5038-83), welded by high-frequency lap welding method, used for spiral seam high-frequency welded steel pipe for pressurized fluid transportation. Steel pipes have strong pressure bearing capacity, good plasticity, and are easy to weld and process into shapes; Spiral seam submerged arc welded steel pipes (SY5037-83) for general low-pressure fluid transportation, made by double-sided automatic submerged arc welding or single-sided welding method, are used for submerged arc welded steel pipes for general low-pressure fluid transportation such as water, gas, air, and steam

The commonly used standards for spiral steel pipes nowadays are generally divided into: SY/T5037-2000 (departmental standard, also known as spiral seam submerged arc welded steel pipes for ordinary fluid transmission pipelines), GB/T9711.1-1997 (national standard, also known as technical delivery conditions for oil and gas industry transmission steel pipes Part 1: A-grade steel pipes), API-5L (American Petroleum Institute, also known as pipeline steel pipes), SY/T5040-92 (spiral seam submerged arc welded steel pipes for piles). Spiral pipe material: Q235A,Q23b,0Cr13、1Cr17、00Cr19Ni11、1Cr18Ni9、0Cr18Ni11Nb. Q345 L245 L290 X42 X46 X70 X80

Email:

Email:.jpg)

.jpg)

.png)